Having collected the kit and stripped the donors I need to check what had been built and what hadn’t, what needed rebuilding and what was missing.

John appears to have fitted the pedal box, the engine and all of the aluminium panels. The engine mounts were expertly made and the aluminium panels had all been fitted correctly, with sealant and rivets. The pedals were fitted but not torqued up. Everything else was still pretty much unbuilt which was good, I was pretty much building the whole car from scratch and I didn’t have to mark Johns homework.

I gave the brake callipers from the donor a good going over then sent them off to Big Redd to refurbish, more on these in another article.

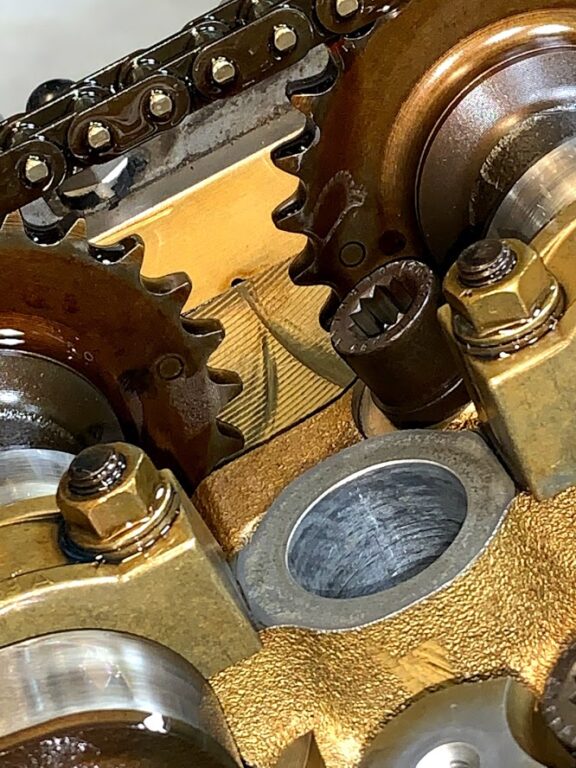

Once the brakes were posted and on their way it was time to hoist the engine out and carry out some maintenance and checks. One bolt on the water-pump was seized and broken so I had to drill that out before replacing it and the full cambelt and rollers. The cambelt is interesting to set up, you align the cam wheels as usual, but you set the belt tightness by measuring the length of the tensioner spring to be between a range of 5mm. I took my time and got it done, it was fun and a learning experience.

One end completed and round to the other end to change out the flywheel and clutch. The flywheel on the engine was not suitable, it was the sort that has been sold as performance but are made from dual metals and can fail momentously. Down the road from me is TTV racing who made a flywheel up to my spec. I measured 300,000 times and then raised the order with them. It was not cheap so I was very concerned that I had measured wrong at some point. Once supplied however, it fitted perfectly, lined up to the hall sender and let me mount the clutch.

Clutch fitted, it was time to mount the gearbox and then start putting it all in place and checking for fitment…. it fitted!

In the next phase its time to add suspension components, check bodyshell clearance and then start on the wiring.